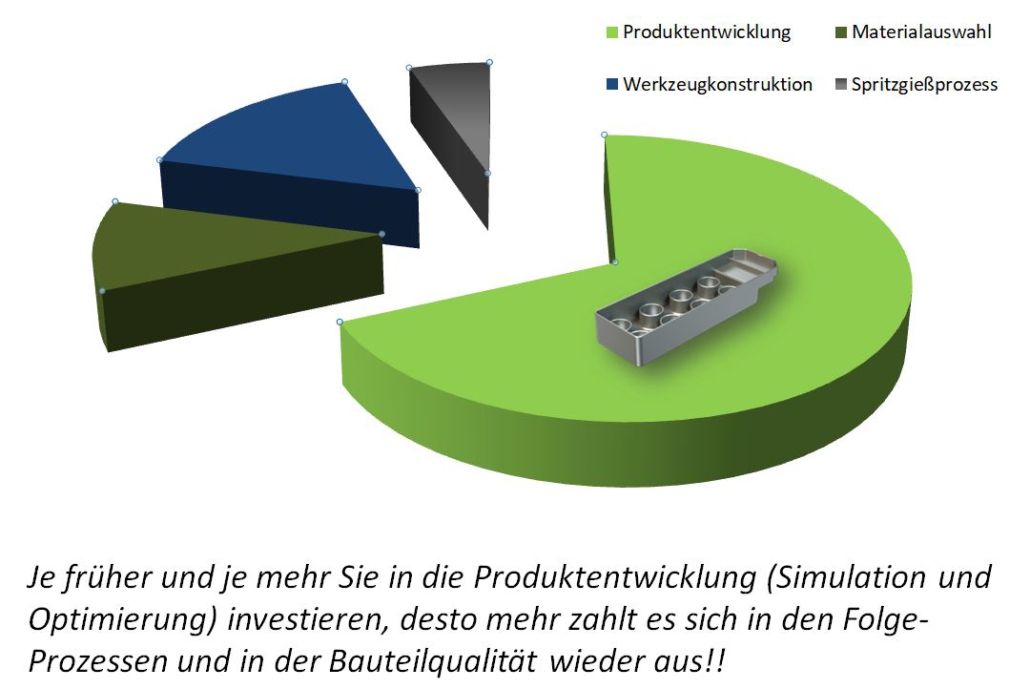

VORKON

What is VORKON and why is it so important?

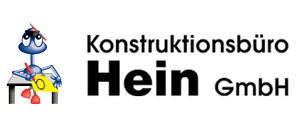

You have the biggest influence on your part quality during the development of the product. This is where the right course for the future is set. It may takes more time at the beginning, e.g. in simulation and for optimization, but you’ll save multiple of the initial investment at the end. VORKON provides in the early stage of product development and / or for the first calculation valuable hints and preliminary concepts within only a few days. Therefore it allows you to stay ahead of possible competitors in terms of tender preparation and ensures advantages for the further course of the project.

Our offer:

Notes for

- filling behaviour

- fibre orientation

- reasonable wall thicknesses

- weld lines

- air trap

- hot spots

- undercut

- potential for optimization

Your benefits:

- early detection of potential for optimization

- better calculation of quotations and projects

- more efficient follow-up processes

- Avoidance of unnecessary follow-up costs for the project

What information do we need in advance?

- 3D data of the part

- exact material name

- information on details on prerequisites or considerations

- Sample parts, no. of cavities, tool draft and technology to be used

With VORKON you can:

- realize optimizations in time

- select suitable procedures in time

- quality/process oriented calculation

- discuss tasks with partners in good time

- qualify against the competitors (quotations)

- the costs of VORKON can be credited to the subsequently injection moulding simulation

- errors, costs and delivery time can be reduced

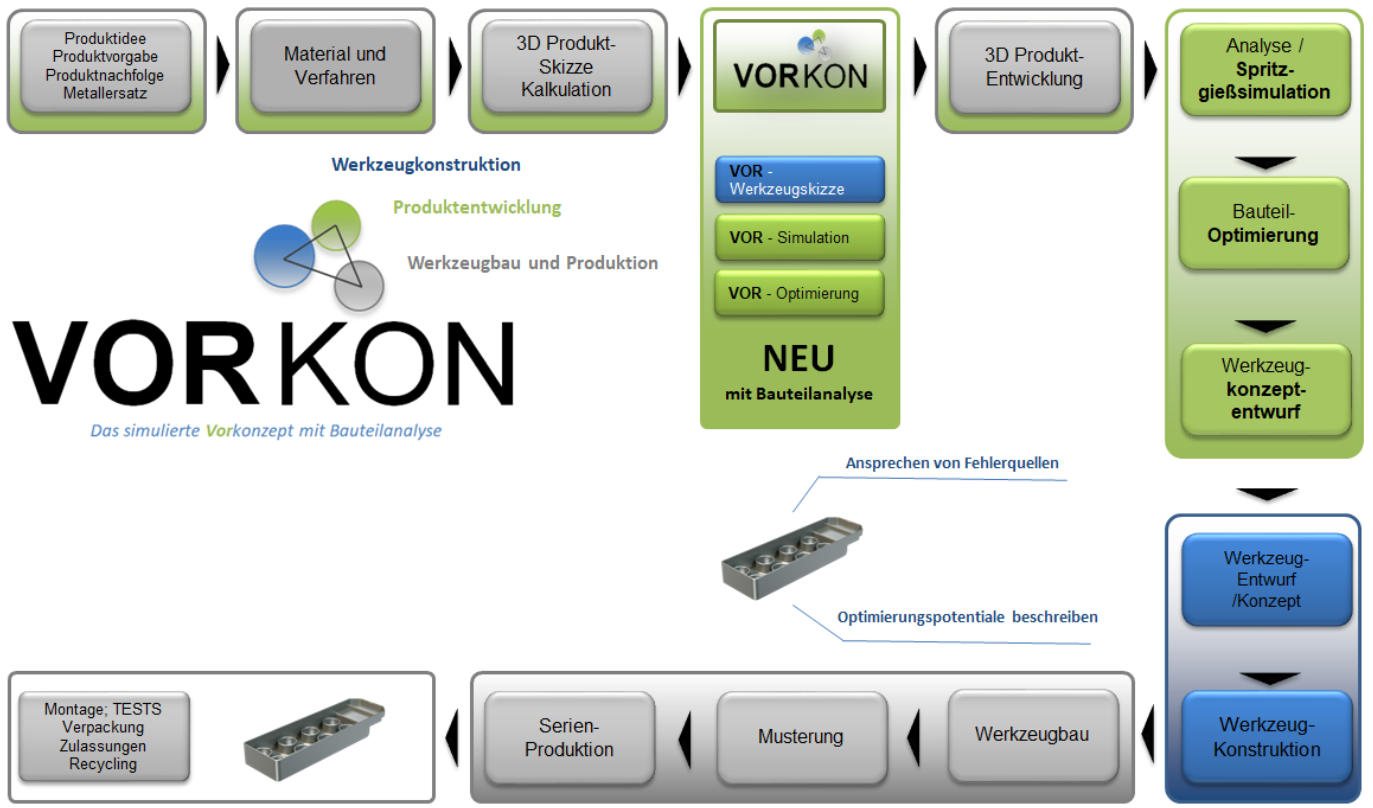

VORKON is a simplified and forward brought simulation considering known features

- mould tool sketch

- simulation

- part analysis

… to tap the full potential of optimizations and process-/needs-oriented decisions

VORKON simulation

- NO process values

- NO mould tool data

- simple temperature control

- simple gating

- basis tool sketch

VORKON simulation – results

- filling behaviour (trend)

- weld line (trend)

- post-pressure (trend)

- sink mark potential (trend)

- wall thickness differences

2-4 days delivery time + report

under 1000€

ordinary injection injection moulding simulation – results

- known or assumed process values

- create or adopt from mould temperature control to the temperature control unit

- regulation of cycle-dependent temperature control

- construction or assumption of the gating situation from the machine nozzle to the part gate

Tool injection moulding simulation

- filling behaviour

- weld lines

- effect of post-pressure

- sink mark potential

- wall thickness differences

- warpage

- cycle time

- filling pressure and clamping force

- hot spots

- surface temperatures

- Air trap and flow front freezing

- consideration of the fibre orientation

- effectiveness of the tool temperature control

5-7 days delivery time + report

price based on effort