Mould design and construction

Mould design for plastic injection moulding has been our core business since the beginning. Our 3D mould design delivers moulds according to the latest state of the art. It combines process reliability, a long service life, optimised venting, tool insulation and high precision.

Our offer:

- injection moulding tools for thermoplastics

- die casting moulds für Duroplaste

- pressure moulding tools for zinc and aluminium

- elastomer moulds for rubber and silicone

- special moulds for hybrid applications

Your benefits:

- latest state of the art

- long tool life

- process realiability

- optimized ventilation (e.g. via vacuum forming)

- high precision

- suitable for industry 4.0

designs for special processes:

- multi-component process

- sandwich process

- foaming process

- tandem solution

- folding core technology

- unscrewing solutions

- injection compression moulding technology

- gas: injection technology, external pressure technology, counter pressure technology, cooling technology

- film back injection moulding

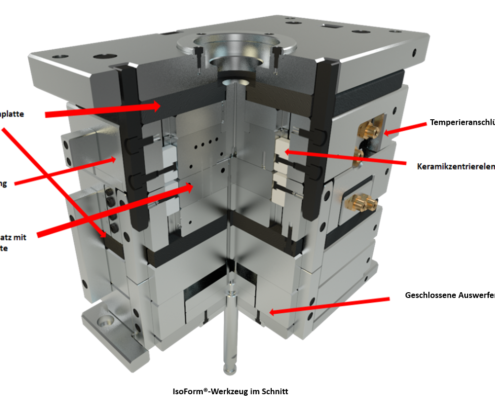

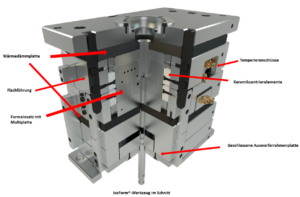

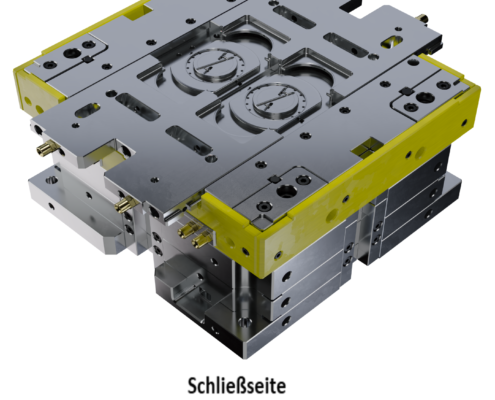

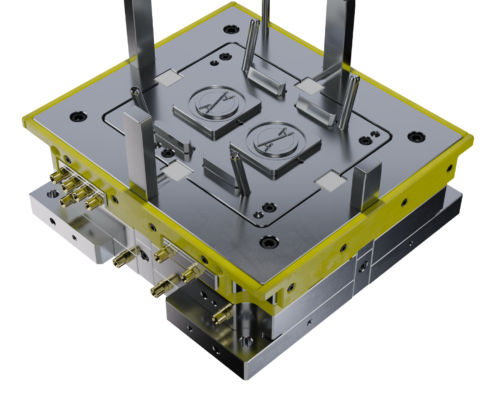

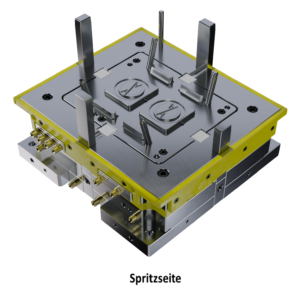

examples of mould design and construction

cross section of moulding tool

example of ejection side

example of injection side

example of mould tool