Temperature control concepts

What is meant by temperature control concepts?

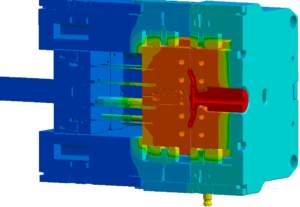

In order to optain good part quality, each plastic material requires its own determined mould wall surface temperature, which should be attained as homogeneously as possible or individually and cycle-dependent.

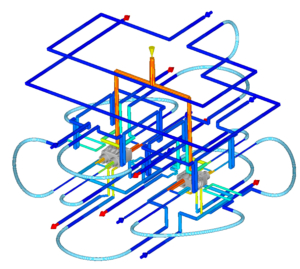

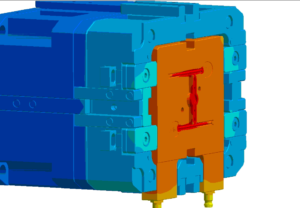

In an injection moulding simulation, a temperature control system is designed prior to mould design, which shows the heat exchange on the mould surface and its effects on the product in the injection moulding process.

The temperature control is realized by drilling, vacuum brazing, laser melting, additive manufacturing or special materials with a close to the contour or cycle-dependent effect. Temperature control bores should always be round and connected for forced circulation.

our offer:

- simulation of temperature control

- design of the temperature control

- close-to-the-contour, cycle-dependent and / or variothermal temperature control

- various media:

- water (up to 428°F), oil, air

- coolant medium (CO2) etc.

- HeiNo® redirection element

Your benefits:

- shorter cycle time

- high surface quality

- less wear at the tool

- process-reliable production

- high quality of moulded part

Example of mould temperature control

Example of mould temperature control