Trouble Shooting

Problems with a part? We have the solution!

We interpret moulded part defects and develop constructive solutions to eliminate them.

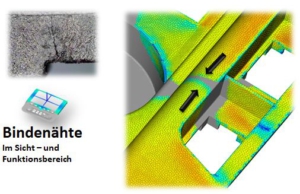

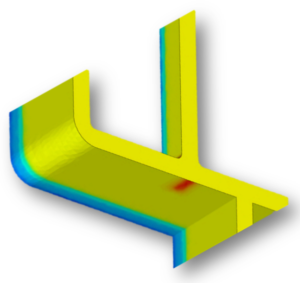

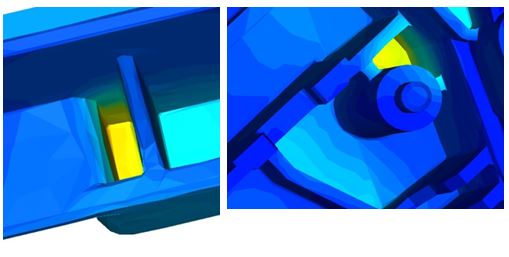

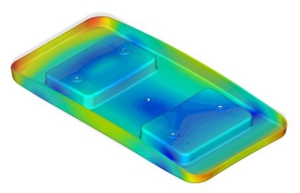

Using an injection moulding simulation, for example, we ensure that no ventilation problems occur or develop new ventilation options for you.

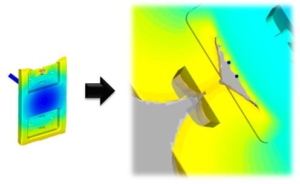

In case of part failure, we carry out part optimisation using FEM calculations and injection moulding simulations and then find ways to ensure that your part will meet future requirements by modifying the design of the part and optimising the mould (e.g. sprue).

Our offer:

- interpreting part defects

- perform part optimization

- developing constructive solutions

- check solutions and simulations

- CT for reducing sample runs

Your benefits:

- optimization suggestions secured by simulation and FEM

- correction of part defects

- fewer sample runs

- avoiding potential sources of defects in the future

part defects that can be avoided

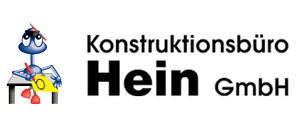

weld line

ventilation

burners

vacuole

wall thicknesse-rib ratio

warpage

We learn from mistakes

Thus the number of mistakes also represents the experience made. TTo avoid making all the mistakes by yourself and to prevent repeating, it makes sense to archive the mistakes made and document the solutions of the problems. So, today we are available for you to get potential problems under control quickly and economically.

We mention here only some of the problems that can arise during the implementation of plastic parts: diesel effect, burner, streaks, warpage, sink marks, thread formation, unfavourable gating definition or incorrect gating position, cold slug, missing dead runner, deformation during demoulding, formation of deposit in the mould, visible or non-loadable weld line, jetting, torn integral hinge; gas bubbles in the part, black clouds, dull areas, halo formation, gloss differences, insufficient mould temperature control, record effect, burr, visible ejector mark, stress whitening, stress cracks, air inclusions, vacuoles, demoulding grooves.

Let us analyse the defect, record the solution and, if desired, eliminate the problem with you or the partners in our network and document the cause so that it cannot be repeated.We solve your problems!