Spritzgießsimulation und Prozessoptimierung

Die Praxis zeigt uns: In der Produktentwicklung von Kunststoffteilen ist eine Spritzgießsimulation für einen optimal verlaufenden Prozess unumgänglich. In einem virtuellen Raum wird der Spritzgießprozess im gesamten durchgespielt, Formteil- oder Werkzeugfehler werden aufgezeigt, ohne dass die Maschinen reale Teile fertigen. Den größten Einfluss auf die Bauteilqualität haben Sie zu Beginn des Entwicklungsprozesses. Hier werden die entscheidenden Weichen gestellt und bereits jetzt entschieden, ob Gutteile bei einer ersten Musterung möglich sind, oder nicht. Korrekturschleifen in einem späteren Prozess können meist komplett vermieden werden. Es lohnt sich also für Sie, am Anfang etwas mehr Zeit in die Spritzgießsimulationen und Optimierung zu investieren. Nachfolgend sparen Sie dafür mehrfach an Zeit und Geld ein.

Mit uns an Ihrer Seite, schaffen Sie es, Formteilfehler und Korrekturschleifen zu vermeiden und Ihr Produkt erheblich schneller auf den Markt zu bringen.

Unsere Leistungen – gute Simulationsergebnisse sparen langfristig Kosten

Mit der Spritzgießsimulation haben wir das Ziel eine prozesssichere Produktion und eine fehlerfreie und optimale Bauteilqualität zu erreichen.

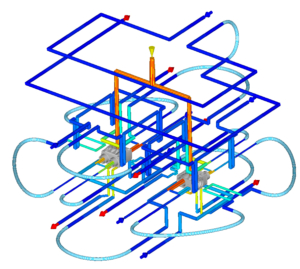

Simulation des Fließverhaltens des Kunststoffes um Lufteinschlüsse und Bindenähte erkennen, vermeiden oder optimieren zu können.

Simulation der Nachdruckwirkung um Einfallstellen, Vakuole und Glanzgradabweichungen vermeiden zu können.

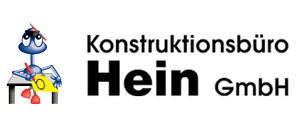

Simulation der Formteiltemperierung mit Auswirkungen auf Füllung, Schwindung und Verzug.

Simulation des Angusssystems und der Angussposition als Grundlage für die Festlegung oder Optimierung der Wandstärkenverhältnisse

Über die Manipulation von Faserorientierungen kann der Verzug und die Bauteilfestigkeit, sowie die Sichtbarkeit von Bindenahtpositionen beeinflussbar werden.

Die Simulation von Einlegeteilen hilft Bindenahtprobleme und thermische Einflussgrößen zu ermitteln, so ermöglichen wir beste Qualität und geringe Kosten für die Fertigung.

Die Spritzgießsimulation liefert viele wichtige Daten für eine anschließende Bauteiloptimierung. Diese ist der erste Schritt zu einem großen Prozessfenster und hoher Bauteilqualität.

Auf Grundlage der Erkenntnisse aus der ersten Bauteilgeometrie, die in einer Simulation betrachtet wurde, werden die Bauteiloptimierungen, die Trennung, die Entformung, die Angussauslegung und die Temperierung bestimmt.

Nach der Bauteiloptimierung wird die Folgesimulation gestartet, um das Ergebnis zu dokumentieren oder weitere Anpassungen zu bestimmen.

Besondere Verfahren werden mit speziellen Vorgehensweisen bearbeitet:

Durch Übergabe der Faserorientierung an ein FEM-System kann Auswirkungen auf die Belastbarkeit des Bauteils haben.

Durch Varimos-DOE (design of Experiments) können Einflussfaktoren zu Steuerelementen für die Einhaltung der Bauteilqualität werden.

Je nach Verfahren können Luftmitnahmen (z.B. PU) angezeigt und gezielt durch Überlaufentlüftungen vermieden werden.

Keyfacts

1. Optimierungspotentiale: Durch die Spritzgießsimulation können Bauteilfehler analysiert und durch die Anpassung der Bauteilegeometrie Fehlerquellen, wie z.B. der Verzug deutlich reduziert werden.

2. Verhinderung von Folgekosten: Durch Korrekturschleifen verteuert sich das Formwerkzeug bis zu einem Vielfachen und wird mit jeder Änderung beschädigt. Bezieht man den Prozess des Werkzeugentwurfs mit in den Spritzgießsimulations-Prozess ein, können diese Korrekturschleifen im Wesentlichen vermieden werden. Die Kombination aus Spritzgusssimulationen und Analysen spart Kosten, die Machbarkeit wird geprüft und Werkzeugauslegung, Konstruktion und Spritzgußprozess können aus Basis der ermittelten Daten angepasst werden.

3. Herstellverfahren: In der Spritzgießsimulation wird auch analysiert, mit welchem Verfahren das Bauteil optimal hergestellt werden kann. Beispiele hierfür sind: Variotherme Prozessführung, Gasinnendrucktechnik oder Sandwichspritzgießen.

Keyfacts

- Werkzeugskizze:

Die VorKon-Spritzgießsimulation liefert Informationen über Formtrennung, Entformungslösungen, Angussart-/ und position, Machbarkeitsbewertung und Sonderfahren. - Vor-Simulation:

Die VorKon-Spritzgießsimulation erfolgt mit vereinfachter Temperaturannahme und vereinfachter Anspritzung. - Bauteilanalyse:

Die Bauteilanalyse liefert z.B. Daten für Füllverhalten, Bindenähte, Lufteinschlüsse, Nachdruckwirkung, Wandstärkenverhältnisse, mögliche Vakuolenbildung und weitere Formteilfehler. - Bei der ersten Musterung ein Gutteil:

Durch die sehr frühen Betrachtungen mittels einer vereinfachten Spritzgießsimulation können wir leicht vermeidbare Korrekturschleifen in der Produktion vermeiden. Die resultierenden Simulationsergebnisse liefern realitätsnahe Materialdaten und unterstützen die Prozessanpassung sowie die Entwicklung und Gestaltung.

VorKon Simulation bietet präzise ist-Daten

Die größte Wirkung auf eine kostengünstige, schnelle und prozesssichere Umsetzung Ihres Produktes haben Sie zu Beginn des Entwicklungsprozesses. Und damit meinen wir ganz am Anfang – noch vor der eigentlichen Produktentwicklung oder Serienproduktion.

Anders ausgedrückt: Der frühe Vogel fängt der Wurm!

Unsere VorKon-Methode liefert hier durch eine reale Spritzgießsimulation erste Informationen u.a. über Füllverhalten, Faserorientierung, sinnvolle Wandstärken, Lufteinschlüsse, Bindenähte, Hotspots und erforderliche Entformschrägen. Auf dieser Grundlage lassen sich durch die Bauteilanalyse erste Optimierungspotentiale simulativ mithilfe der Software aufzeigen.

Das Besondere dabei ist, dass diese Daten auch bereits jetzt schon wichtige Informationen über ein vorläufiges Werkzeugkonzept, wie z.B. Anspritzposition und Entformschrägen liefern.

Formteilfehler

- Formteilfehler interpretieren: Fehler in der Bauteilgestaltung und in der Werkzeugkonstruktion haben in den letzten Jahren stark zugenommen. Die Ursachen für die Fertigungsprobleme sind oft nicht für jeden erkennbar.

- Bauteiloptimierungen durchführen: Das Fenster möglicher Verbesserungen ist mit einem bestehenden Werkzeug klein. Es gilt also die noch verborgenen Optimierungspotentiale innerhalb der Prozessparameter zu finden, die im vorhandenen Werkzeug noch umsetzbar sind, mit unserem Know-how verhindern wir als Dienstleister Mehraufwand, berücksichtigen Wünsche in jedem Bereich und bieten eine präzise Analyse.

- Werkzeugänderungen durchführen: Dazu liefern wir Ihnen genaue Angaben in Schnittdarstellungen für das Bauteil und für das Werkzeug.

Mehr Effizienz in der Produktion, deutlich kürzere Zykluszeiten, Gutteile bei der ersten Musterung. Wir zeigen wie’s geht!