Das Werkzeugkonzept der Zukunft

Automatisierter Fertigungsprozess – nachhaltig und energieeffizient

Ein Blick in die Zukunft zeigt, dass eine zukünftige Automatisierung in der Kunststoffverarbeitung unumgänglich ist. Zukunftsfähige Werkzeugkonzepte müssen daher vor allem auch für automatisierte Fertigungsprozesse geeignet sein.

IsoForm®-Werkzeuge erfüllen diesen Anspruch, weil sie energieeffizient, nachhaltig und schnell die Prozesstemperatur erreichen können.

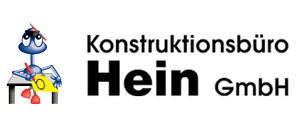

Mittige Zentrierung und Auswerfersystem

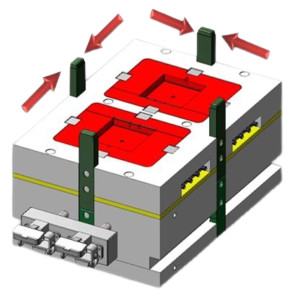

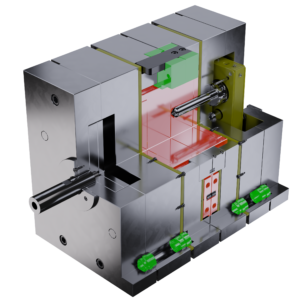

Zentrierung

- Durchgängig mittige Zentrierung der Einsätze, Formplatten und Formhälften zueinander

- Hohe Präzision

- Unterschiedliche Wärmeausdehnung wird kompensiert

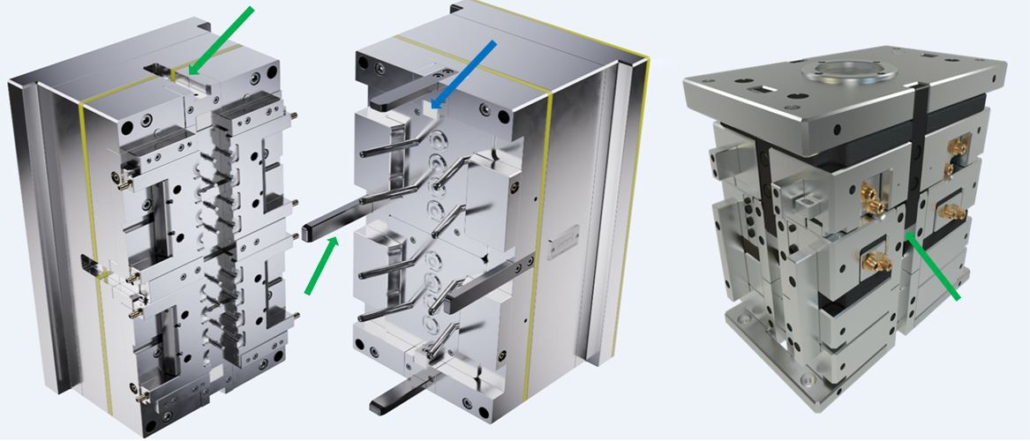

Die Zentrierung erfolgt für die Formeinsätze mit Keramikelementen (2W/mK, blauer Pfeil, Abb. mitte), die als einzige Verbindung zwischen dem „heißen“ Formeinsatz und dem Formträgerrahmen auch zur thermischen Trennung dienen.

Außen werden Flachzentrierungen (grüne Pfeile, Abb. links) eingesetzt, die ein Klemmen und Fressen von Führungen und Zentrierungen durch unterschiedliche Ausdehnungen wie bei Säulen vermeiden.

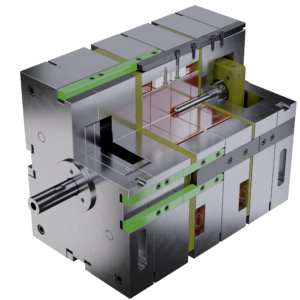

Die mittige Zentrierung auch über die Platten des Formaufbaus (grüner Pfeil, Abb. Rechts) ermöglicht eine bedarfsgerechte Anpassung der Temperierung sowie eine einfache, schnelle und präzise Montage und Demontage des Werkzeugs.

Auswerfsystem

- Funktionsorientiertes Auswerferplattensystem

- Maximale passive Abstützung

- Hohe Standzeit

- Geringe Durchbiegung

- Vermeidung von Gratbildung

Wieso benötige ich IsoForm® und was sind die Vorteile?

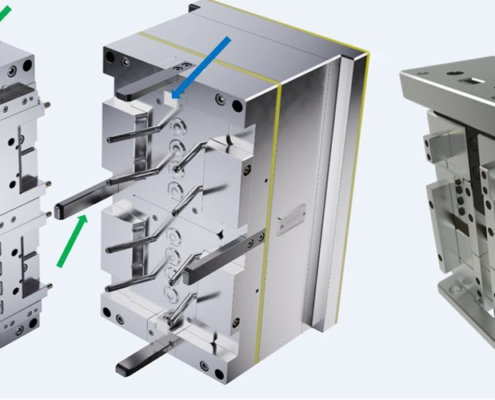

Die konsequente thermische Isolierung des Konturbereiches bietet neben einer erhöhten Prozesssicherheit enorme Vorteile für den Zeit- und Energiebedarf:

Die nachhaltigen und äußerst effizienten Werkzeuge benötigen beim Aufheizen für die vorliegende Anwendung bis zu 95% weniger Energie im Vergleich zu konventionellen Werkzeugen.

Der Energieeintrag zum Aufheizen eines Werkzeuges für den Hochtemperaturbereich (z.B. PEEK / Gummi / Silikon / Duroplaste) wird in gleichem Maße reduziert.

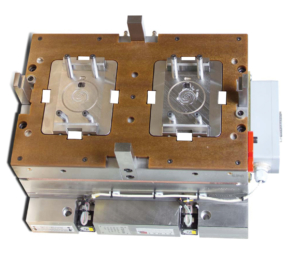

Werkbild Single/Durotherm – Für ein Premium-Versuchswerkzeug

Vorteile auf einen Blick

- Konsequente Isolierung formgebender Teile zum umgebenden Werkzeug

- Reduzierte Durchbiegung – geringe bis keine Gratbildung

- Kürzere Rüstzeiten, Aufheizphasen

- Konsequente Mittenzentrierung » geringerer Formversatz

- Ideal als Stamm-/Familienwerkzeug, als Wechselwerkzeug mit Verbleib auf der Maschine

- Zusätzliche Isolierung zum Heißkanal möglich (minimiert Gegenheizen)

- Ideal für zyklusabhängige Temperierung

- Reduzierung von Energiekosten, v.a. im Hochtemperaturbereich

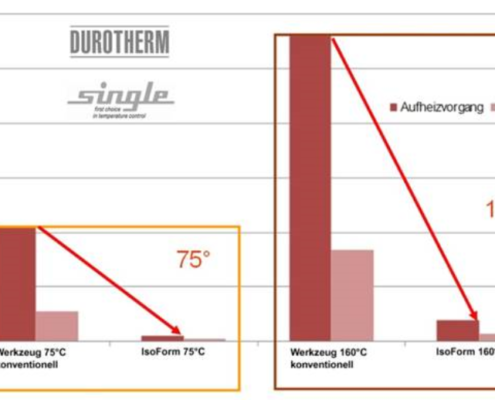

Gegenüberstellung der Aufheizphase bei 75°C und bei 160°C

Die dargestellte Anwendung zeigt in der Praxis, dass man nicht nur mit einem Bruchteil des Energiebedarfs auf Prozesstemperatur ist, sondern auch dass man dieses Ziel hier bereits in 1/5 bis 1/10 der Zeit im Vergleich zu einem konventionellen Werkzeug erreicht.

- Für Elastomere, Thermoplaste, Duroplaste und Druckguss

- Höhere Prozesssicherheit, weil Gestaltung und Konzeption Fehlerquellen ausschließen

- In allen Größen – mit IsoForm®-Vorteilen – erhältlich

- Spannaufnahmen nach üblichem Standard möglich

- IsoForm®-BASIC weitgehend kostengleich mit marktüblichen Formaufbauten – mit mehr Vorteilen

- BASIC-Variante jederzeit mit Keramikzentrierungen nachrüstbar

Werkzeugwechselsysteme

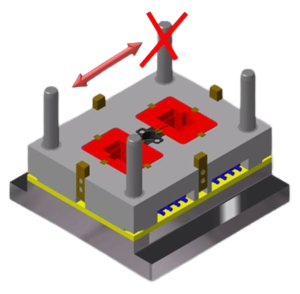

IsoForm®: Unterschiedliche Längenausdehnung wirkt sich nicht auf die Zentrierelemente aus. So ist eine genaue Passung möglich.

Werkzeugwechselsysteme

Unterschiedliche Längenausdehnung zwischen Spritzseite und Schließseite bei unterschiedlichen Vorlauftemperaturen.

IsoForm® Werkzeugwechselsysteme

Wechselsysteme

- Alle IsoForm®-Vorteile

- Mehrfachnutzung des Stammwerkzeugs » günstige anteilige Werkzeugpreise

- Schneller, einfacher Wechsel der Produktion unterschiedlicher Bauteile

Im IsoForm®-Programm gibt es für die Mehrfachnutzung Normalienvarianten, bei denen die Einsätze oder ganze Formplatten (auch mit Schiebern und/ oder Auswerfern) von der Trennebene aus gewechselt werden können. So erreichen Sie einen schnellen thermisch getrennten Werkzeugwechsel mit präziser Zentrierung, ohne Leckagen und Probleme, bei Bedarf mit Transpondern und vollautomatisch.

Gewissermaßen kann man dabei die Investition für das Modulstammwerkzeug der Investition der Maschine zurechnen und erreicht so günstigere Werkzeugpreise.

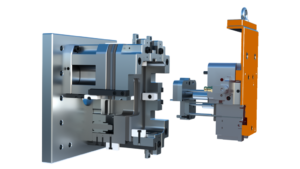

Wechselformeinsätze

- Nur Formeinsatz mit Auswerferplatte wird gewechselt

- Für kleine projizierte Flächen

- Montageblech zum Wechseln und zum Schutz der Kontur

- Für manuellen Wechsel geschraubt oder mit Riegeln

- Auch für automatisierten Wechsel erhältlich

Einsatzwechselsystem

Einsatzwechselsystem

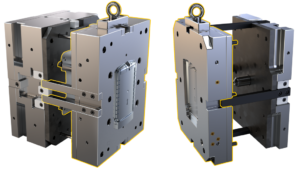

Plattenwechselsystem

Wechselplattenwerkzeug:

- Wechsel der Formplatten

- Für größere projizierte Flächen

- Konturbereiche werden mit Abdeckplatten geschützt

- Reduzierte erforderliche Lagerkapazität

- Hohe Prozesssicherheit und präzise Zentrierung

Wechseleinsätze:

- Mit Schiebern

- Mit Kernstiften für Hülsenauswerfer

- Mehrere Anwendungen in einem Werkzeug

- Energieeffizient und nachhaltig

- Schnell und prozesssicher in der Fertigung

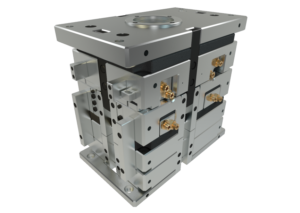

ISOFORM® FÜR THERMOPLASTE

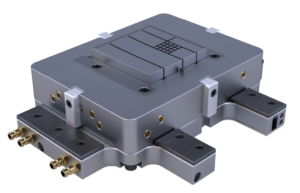

Temperierung

Die Werkzeuge sind so individuell temperierbar, dass sie zur einen Seite mit der Wassertemperierung arbeiten und auf der anderen Seite dem Kältemitteladapter (siehe Abb. Oben blauer Pfeil) das Andocken ermöglichen, während auf der gegenüber liegenden Seite die Sensorik und/oder die Gasinjektion anzuschließen wäre.

IsoForm® Werkzeug

- Thermische Trennung

- Mittige Zentrierung

- Individuell temperierbar

- Normalienaufbauten in jeder Größe

- Schieber und isolierter Heißkanal

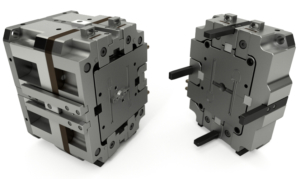

Schieberwerkzeug

Schieberwerkzeuge stellen den Großteil der realisierten IsoForm®-Spritzgießwerkzeuge dar. Eine Besonderheit ist dabei die immer mittige Führung der Schieber, die zu dem immer mittigen Zentriersystem der IsoForm®-Werkzeuge passt.

Ein weiteres Merkmal ist die Isolation des Schiebers und seiner Führungselemente gegen den Formträgerrahmen, wie wir es schon von den Formeinsätzen kennen. Aufschlagstücke dienen der Feinabstimmung des Werkzeuges.

IsoForm® für Thermoplaste

IsoForm® für Gummi, Silikon und Duroplaste

Für die Verarbeitung vernetzender Werkstoffe ist die thermische Trennung zwischen dem kalten Bereich der Materialzuführung und dem geheizten Konturbereich elementar wichtig.

Mit IsoForm® können Sie mit Wasser bis zu 240°C (bis 180°C sogar zyklusabhängig) temperieren. Mit zyklusabhängiger Temperierung wird so während der Füllung ein „Anvernetzen“ in der Kavität vermieden. Dann kann die Vernetzung gezielt gestartet werden.

Silikon:

Im Beispiel rechts wurde die Umspritzung eines Einlegeteils des Werkzeugherstellers Heite & Krause GbR mit Silikon umgesetzt.

Die Schieber wurden hier innerhalb des isolierten Formeinsatzes realisiert. Wärmedämmplatten im Trennbereich stellen einen Berührschutz dar.

Keramische Zentrierungen der Formeinsätze sorgen für eine Fixierung der Einsätze und äußere Stollenzentrierungen stellen sicher, dass sinnvolle unterschiedliche Temperierungen keine Funktionsstörungen des Werkzeuges nach sich ziehen.