Bauteiloptimierung – das Optimum aus dem Bauteil heraus holen und Kosten sparen

Form folgt Funktion. Diesen Satz sollte man an die erste Stelle seiner Überlegungen an ein Produktdesign stellen. Häufig werden Bauteile so designt, dass sie zwar optisch gut aussehen, aber den technischen Anforderungen an ihren eigentlichen Nutzen und den Verarbeitungsprozess nicht gerecht werden. Selbst optische Bauteile können nur mit Hilfe sinnvoller Verfahren und mit optimierter Geometrie eine gute Qualität erreichen.

Sie möchten mehr Prozesssicherheit, eine höhere Effizienz im Herstellprozess und die Kosten für unnötige Entwicklungsfehler vermeiden bzw. dauerhaft damit einen höheren Gewinn erzielen?

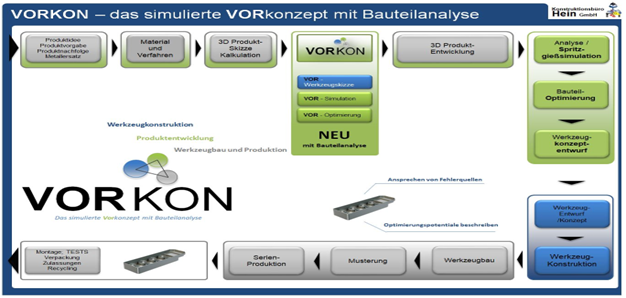

Durch unsere Bauteiloptimierung auf Grundlage der Spritzgießsimulation und unserer Erfahrungen verhelfen wir Ihnen zu mehr Effizienz und Qualität in der gesamten folgenden Produktionskette mit deutlich weniger Folgekosten.

Je früher die Topologieoptimierung erfolgt, desto mehr Bauteil- und Prozessfehler können vermieden werden. Schöpfen Sie frühzeitig das Optimierungspotential aus, um später Gutteile bei der ersten Musterung zu ermöglichen. Wir zeigen wie‘s geht!

Unsere Leistungen: von der Produktentwicklung bis zur Bauteiloptimierung

Jedes Bauteil bringt seine speziellen Ansprüche und auch Herausforderung mit sich. Auf der Grundlage unserer Spritzgießsimulation kann die Bauteiloptimierung aufzeigen, welche Anpassungen und Änderungen sich rechtzeitig abspielen sollten, um die gewünschte Bauteil- und Prozessqualität zu erreichen.

Folgende Aspekte werden in der Bauteiloptimierung betrachtet und mit dem Kunden priorisiert, um ihn umfassend zu unterstützen.

Die Bauteilfestigkeit, die Optik, die Haptik, die Stabilität, die Funktionalität, die Montage und Demontage, die Herstellbarkeit, die Werkstoffeinsparung, Energieeffizienz im Herstellprozess, Kostensenkung, Vermeidung von Bauteilfehlern, das Erreichen von Prozesssicherheit und das Verhindern von Korrekturschleifen, beziehungsweise das Erreichen von Gutteilen bei der ersten Musterung sind Ansprüche, die es zu erreichen gilt.

Es kann eine Anpassung der Geometrie, die Auslegung, ein anderes Verfahren oder auch ein anderer Werkstoff sein, was ihren Prozess und die Qualität erst möglich machen und Sie vor hohen Folge- und Materialkosten verschont!

Die Bauteiloptimierungen sind am Effektivsten, wenn man sie frühzeitig einfließen lässt. Je später man im Prozess ist, desto weniger Verbesserungen können umgesetzt werden. Bei Trouble Shootings nach der ersten Musterung können so nur noch kleine Anpassungen getätigt werden, da größere Änderungen meist weitere Bauteile (Baugruppen) betreffen, welche dann auch im laufenden Prozess gestoppt werden müssten.

Jede Verbesserung ist auf einer Spritzgießsimulation oder/und einer FEM-Analyse aufgebaut. Aus der Nachbildung entnehmen wir Resultate, die wir mit unserer Erfahrung und Kompetenz nach einer ersten Analyse zu Bauteiloptimierungsvorschlägen ausarbeiten.

Es ist aus unserer Sicht grundsätzlich fahrlässig eine Bauteiloptimierung zu vernachlässigen. Die Topologieoptimierung mit Spritzgießsimulation gehört in die Vorgaben für jedes Pflichten- und Lastenheft für die Produktentwicklung, denn es sollte vor der Vergabe der Werkzeugherstellung abgeschlossen sein.

Unsere Bauteiloptimierungen werden in einem ausführlichen Bericht zur Nachbildung und auch zur Geometrieoptimierung dokumentiert und mit Ihnen durchgesprochen. Die Geometrieoptimierungen werden in 2D-Schnitten eingezeichnet und Schritt für Schritt dokumentiert.

Wir freuen uns auf Ihre Aufgabenstellung !

Mehr Effizienz in der Produktion, deutlich kürzere Zykluszeiten, Gutteile bei der ersten Musterung. Wir zeigen wie’s geht!

Troubleshooting

Hinweis: Die folgenden Infos benötigen Sie nur, wenn Sie die oben genannten Empfehlungen auf dieser Seite nicht berücksichtigt haben.

Die Anforderungen an Kunststoff-Bauteile hinsichtlich Beständigkeit, Design und Festigkeit werden immer höher. Es gibt enorm viele Parameter, welche in einem Herstellungs- und Entwicklungsprozess Einfluss auf die endgültige Bauteilqualität haben. Obwohl dies mittlerweile kein Geheimnis mehr darstellt, wird noch zu viel an den Arbeitsschritten: Spritzgusssimulation, Bauteiloptimierung und Werkzeugkonzept gespart.

Häufig kommt es dazu, dass entsprechende Simulationen erst sehr spät in einem Entwicklungsprozess durchgeführt werden. Manchmal erst dann, wenn das endgültige Produktdesign (Topologie und Topographie) feststeht, bzw. das Werkzeug schon gebaut und erste Musterungen fehlgeschlagen sind. Jeder weiß, dann wird es richtig teuer, weil das bestehende Werkzeug geändert werden muss. Diese Formteilfehler müssen jedoch nicht geschehen und ließen sich relativ leicht verhindern, wenn man früh genug wichtige Daten aus einer Spritzgusssimulation und FEM erhält und auf Grundlage dieser Daten eine Bauteiländerung schon in einer sehr frühen Phase vornimmt.

Wir interpretieren Formteilfehler am Bauteil und am Werkzeug auf der Grundlage von Spritzgießsimulationen, So erarbeiten und liefern wir konstruktive Lösungen und einen guten Vorschlag, um eine vertretbare Produktion zu ermöglichen. Natürlich steht uns dann nur ein minimales Verbesserungspotential zur Verfügung, als in der Produktentwicklungsphase, in der uns noch die Nutzung maximaler Möglichkeiten zur Verfügung steht.

Formteilfehler und daraus resultierende Optimierung

1. Formteilfehler interpretieren: Jeder Fehler hat einen oder oft auch mehrere Gründe. Wir zeigen diese anhand einer Spritzgießsimulation und unseren Erfahrungen im Formenbau und Spritzguss auf.

2. Formteilfehler können sein: Verzug, Oberflächenmarkierungen, wie Schlieren, Bindenähte, Einfallstellen, Brenner, Grat und viele festigkeitsreduzierende Probleme, wie Vakuole und Bindenähte.

3. Bauteiloptimierungen durchführen: Die Bauteiloptimierungen werden bei uns in erster Linie in 2D-Schnitten skizziert und dann Schritt für Schritt dokumentiert. Diese Verbesserungsvorschläge werden dann vom Kunden meistens selbst in deren 3D-Software eingearbeitet. Auf Wunsch auch bei uns. Mithilfe der additiv gefertigten Teile verfügen wir über eine wichtige Komponente im Rahmen der Verbesserung, sie fallen weniger ins Gewicht und unterstützen eine Konsolidierung mehrerer Komponente in einem einzigen Schritt.

4. Lösungen und Nachbildungen überprüfen: Die eingebrachten Anpassungen werden dann in einer Folgesimulation erneut betrachtet, um zu prüfen, ob weitere Optimierungen erforderlich sind.

5. Gerade festigkeitsreduzierende Vakuole bei glasfaserverstärkten Anwendungen können auch gut mit der Computertomographie geprüft werden.